Discover the Conveniences of Using CNC Machining Solutions for Accuracy Design and Production

CNC machining services provide significant benefits for accuracy engineering and manufacturing. By employing sophisticated computer-controlled equipment, these solutions guarantee high degrees of accuracy and effectiveness. This modern technology permits the production of elaborate elements from various materials, minimizing human error and manufacturing time. The benefits prolong past accuracy alone, hinting at much deeper impacts on efficiency and cost-efficiency that are vital for modern-day industries. Checking out these elements discloses a more substantial understanding of CNC machining's role.

Improved Precision and Accuracy

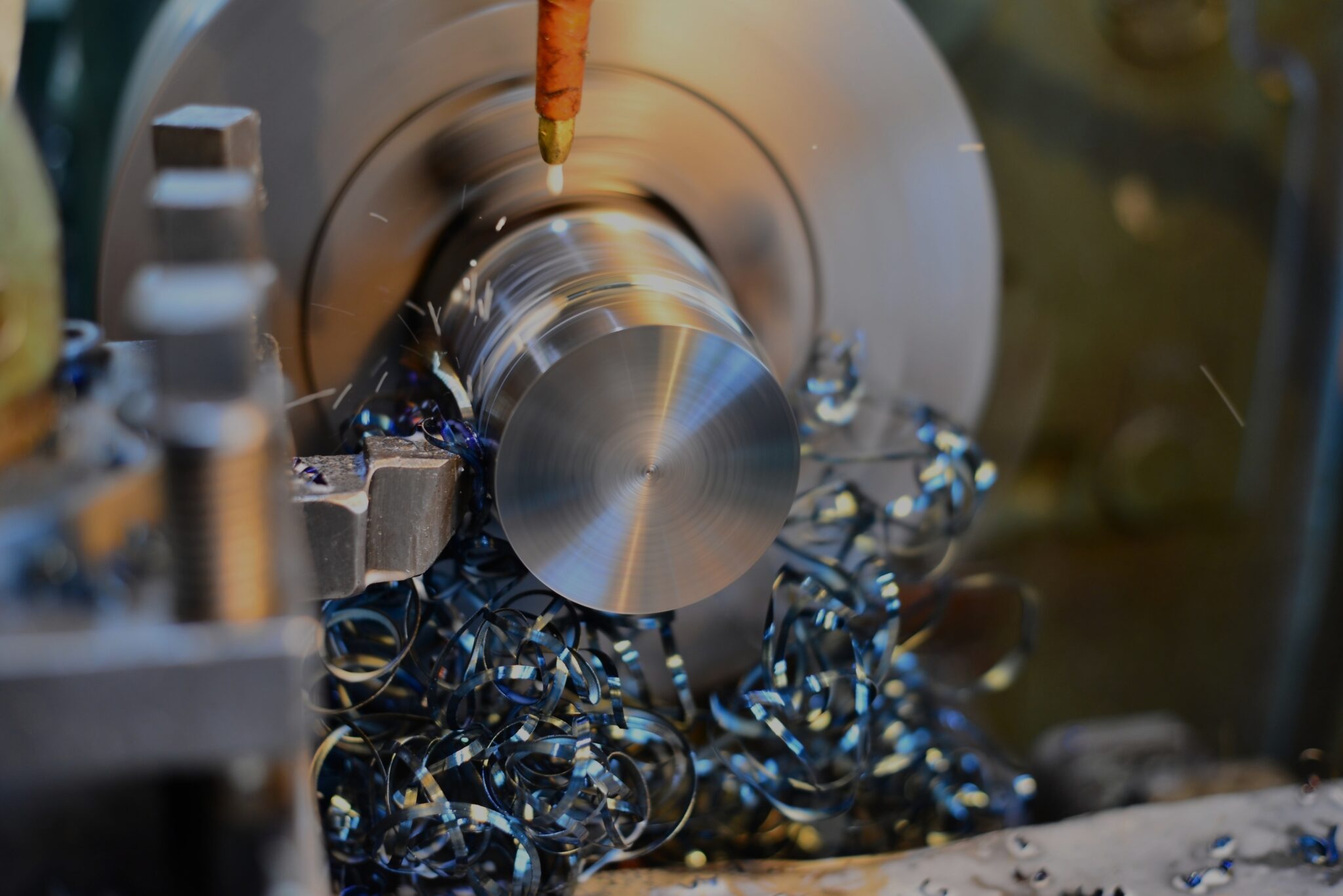

As markets significantly require greater standards, CNC machining services have become a crucial service for accomplishing improved precision and accuracy in engineering applications. These services utilize sophisticated computer-controlled machinery to create complex elements that fulfill stringent requirements. The capacity to program specific measurements decreases human error, making sure that each component is produced to exacting tolerances.

CNC machining is specifically useful in industries such as aerospace, automobile, and medical devices, where precision is vital. The modern technology enables the production of intricate geometries that typical machining methods might battle to accomplish. By employing CAD models, CNC devices can replicate layouts with exceptional integrity, resulting in regular high quality across production runs.

Boosted Efficiency and Productivity

In addition, CNC technology permits the synchronised processing of several elements, causing higher manufacturing prices. The capacity to run makers continually, also throughout non-working hours, makes the most of functional time and source use. In addition, the quick arrangement and transition times connected with CNC machining promote quick adaptation to various job demands, allowing manufacturers to respond swiftly to market demands.

Cost-Effective Manufacturing Solutions

Additionally, CNC machining enables fast prototyping and manufacturing runs, which helps to enhance the manufacturing procedure and lower lead times. The capability to produce complex geometries with very little product waste even more adds to cost savings. fast prototyping. Consequently, firms can assign funds a lot more successfully and purchase various other areas of their operations. Generally, CNC machining solutions supply a reputable path for organizations to boost profitability while preserving high standards in item quality and performance

Versatility in Material Compatibility

The flexibility of CNC machining services in material compatibility is one of its most significant advantages. This capability allows makers to collaborate with a varied range of materials, consisting of plastics, steels, and composites. Each material can be finely machined to meet details design requirements, resulting in parts that are both top quality and practical. Light weight aluminum and steel are frequently utilized for their strength and longevity, while plastics can be chosen for their lightweight and corrosion-resistant buildings. CNC makers are equipped to deal with different product residential properties, making sure that the desired requirements are fulfilled with precision. This adaptability not only improves the style possibilities but likewise enables makers to customize their products to various industry demands, from aerospace to automobile and medical applications. Inevitably, the ability to properly make use of multiple products improves the manufacturing process and broadens the range of innovative design solutions.

Structured Prototyping and Style Model

Improving the prototyping and style version process is a crucial benefit of advanced machining technologies. CNC machining services permit engineers and developers to quickly produce precise prototypes, assisting in quick testing and examination. This performance considerably decreases the time from idea to production, enabling business to repeat layouts quickly based upon real-world feedback.

Additionally, CNC machining's high precision reduces mistakes, making certain that each prototype carefully mirrors the last product requirements. The ability to deal with different products better enhances the design opportunities, permitting for detailed screening throughout different circumstances.

Consequently, companies can fine-tune their from this source items extra effectively, adapting to market needs and consumer preferences. This responsiveness is necessary in today's affordable landscape, where innovation and speed are paramount. Using CNC machining solutions not just increases the development procedure however likewise enhances the general top quality and dependability of the last manufactured products.

Regularly Asked Concerns

What Industries Benefit Most From CNC Machining Providers?

The aerospace, auto, medical, pop over to these guys and electronic devices industries profit most from CNC machining solutions. These markets call for high accuracy, complex designs, and consistent quality, making CNC machining necessary for creating intricate parts and conference strict sector requirements.

Just How Does CNC Machining Compare to Typical Manufacturing Methods?

CNC machining provides higher accuracy, efficiency, and adaptability compared to typical production methods. It minimizes human mistake, allows complex layouts, and permits quick prototyping, inevitably leading to better production high quality and reduced lead times.

What Sorts Of CNC Machines Are Commonly Made Use Of?

What Is the Normal Preparation for CNC Machining Projects?

The common preparation for CNC machining projects generally ranges from a couple of days to a number of weeks, depending upon elements like complexity, material accessibility, job dimension, and the maker's work, influencing total delivery timelines.

Exist Any Kind Of Limitations to CNC Machining Providers?

CNC machining solutions do have constraints, including product constraints, complexity of styles, and size constraints. Furthermore, detailed geometries might need specific tooling, which can raise manufacturing time and costs, influencing overall job expediency.

CNC machining solutions use substantial benefits for accuracy design and manufacturing - tool and die maker. As sectors progressively demand greater standards, CNC machining solutions have arised as a necessary remedy for achieving improved accuracy and Look At This precision in design applications. CNC machining solutions not just improve accuracy yet additionally significantly boost effectiveness and efficiency in making procedures. CNC machining offers greater effectiveness, precision, and flexibility contrasted to standard manufacturing techniques. Frequently made use of CNC devices include CNC lathes, CNC milling equipments, CNC routers, CNC plasma cutters, and CNC laser cutters